|

|

||||||||||||

|

|

||||||||||||

|

THIS PROCEDURE MUST BE CARRIED OUT WHEN EVER AN ENGINE OR TRANSMISSION SWAP IS CARRIED OUT. |

||||||||

|

IF YOU ARE GOING RACING AND USE AN SFI CERTIFIED FLEX PLATE, YOU SHOULD ALSO CONSIDER DOING THIS AS WELL. |

||||||||

|

THE NAME “FLEX PLATE” IS APPROPRIATE. IT FLEX’S TO ALLOW FOR MISALIGNMENT BETWEEN THE ENGINE AND THE TRANSMISSION. IF YOU USE AN SFI APPROVED FLEX PLATE IT WILL BE MADE OF A THICKER MATERIAL THAN THE STOCK PLATE - CONSEQUENTLY IT WILL NOT FLEX. |

||||||||

|

IF THE CENTERLINE OF THE ENGINES CRANKSHAFT AND THE CENTERLINE OF THE TRANSMISSION, ARE MORE THAN 5 THOU (0.005”) APART, THEN EITHER THE REAR MAIN BEARING IN THE ENGINE OR THE FRONT BUSH IN THE TRANSMISSION, OR BOTH, WILL RAPIDLY WEAR OUT. |

||||||||

|

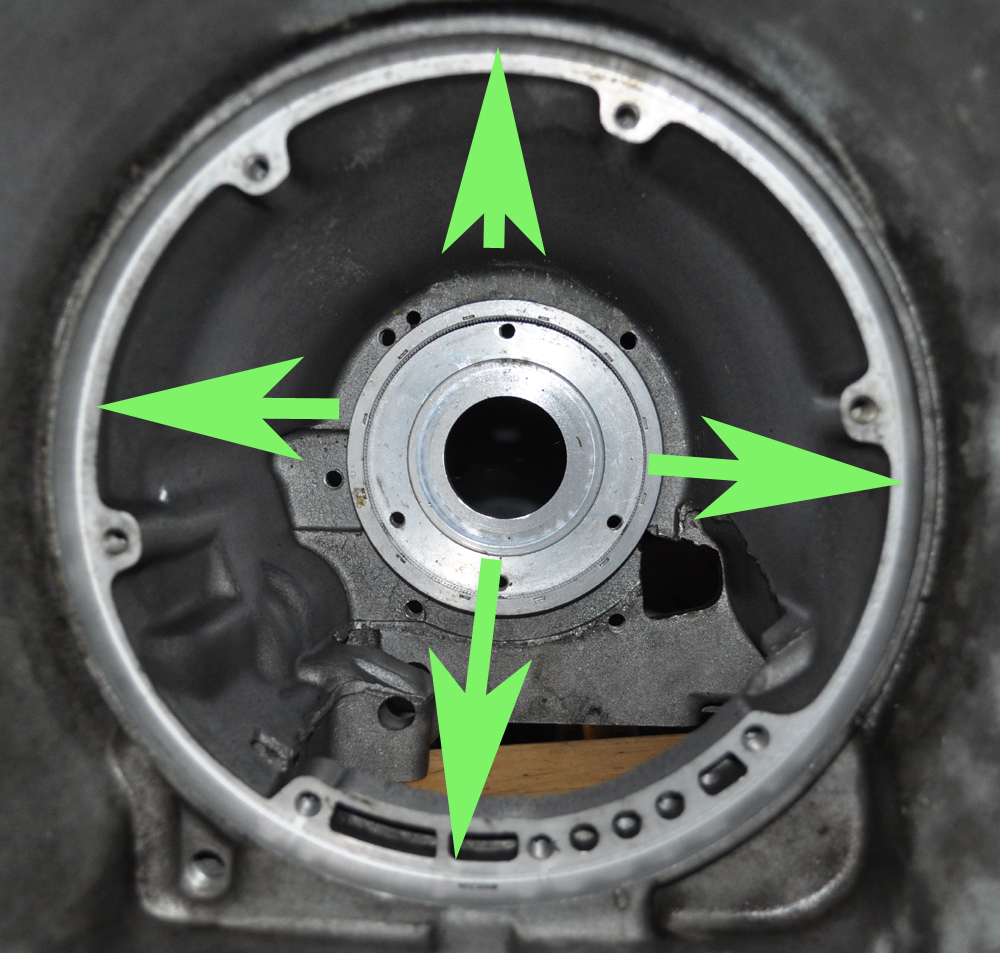

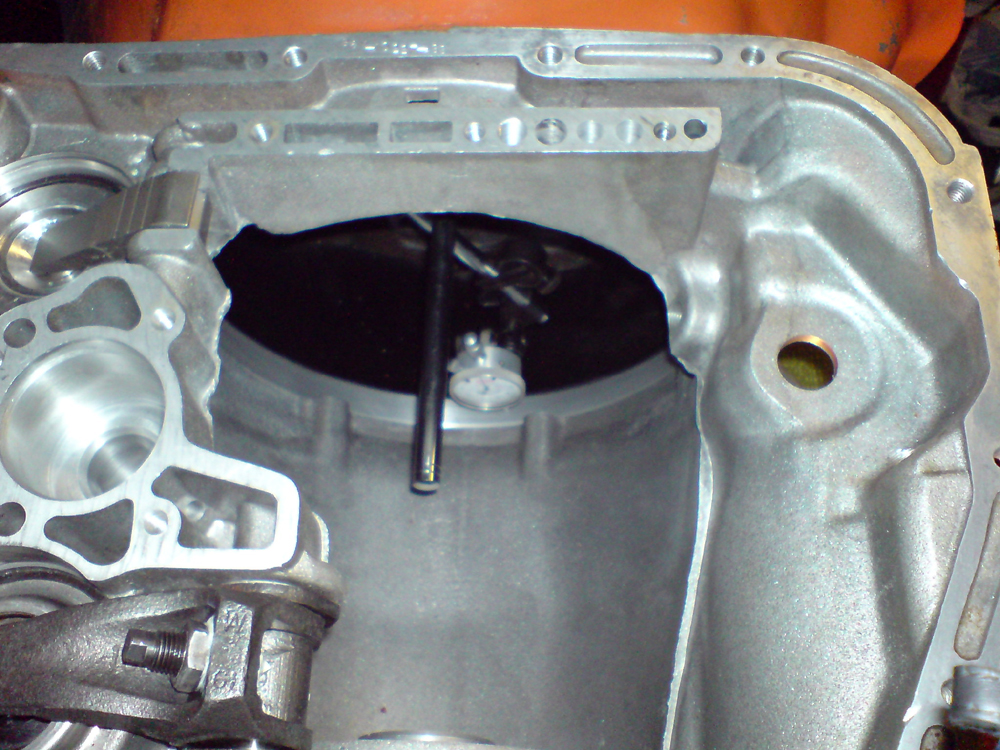

THE EMPTY TRANSMISSION CASE NEEDS TO BE BOLTED TO THE BACK OF THE ENGINE. THE CRANK SHAFT SHOULD HAVE THE FLEX PLATE BOLTED TO IT. A DTI (CLOCK GAUGE) SHOULD BE MOUNTED TO THE FLEX PLATE WITH A MAGNETIC BASE. THE GAUGE SHOULD BE SET TO RUN ON THE FRONT PUMP LOCATION SURFACE. (SEE PHOTO’S BELOW) |

||||||||

|

||||||||

|

BAD PHOTO OF CLOCK GAUGE IN SITU. |

||||||||

|

||||||||

|

ROTATE THE CRANKSHAFT THRU A COUPLE OF REVS. IN THE PROCESS MEASURE THE TOTAL RUN OUT BETWEEN THE CRANK AND THE TRANSMISSION CASING. |

||||||||

|

THE TOTAL RUN OUT SHOULD NOT EXCEED 10 THOU. (0.010”) THIS GIVES A MAXIMUM MISALIGNMENT OF 5 THOU. (0.005”) |

||||||||

|

SO - WHAT EVER THE TOTAL RUN OUT IS - HALF IT, TO GIVE THE MISALIGNMENT. ALSO MARK IN WHICH DIRECTION THE MISALIGNMENT IS IN |

||||||||

|

IF YOUR MEASUREMENT IS OVER 5 THOU (0.005”) MISALIGNMENT. THE LOCATION DOWELS IN THE BLOCK WILL HAVE TO BE REMOVED AND REPLACED WITH A PAIR OF OFFSET DOWELS THAT ARE READILY AVAILABLE. THE OFFSET DOWELS COME IN 7 THOU INCREMENTS. |

||||||||

|

0.007” then 0.014” then 0.021”. |

||||||||

|

CHOOSE THE CORRECT PAIR OF OFFSET DOWELS, AND INSTAL THEM IN THE BACK OF THE BLOCK WITH THE OFFSET TURNED TO REDUCE THE MISALIGNMENT TO BELOW 5 THOU. |

||||||||

|

THEN MEASURE IT ALL AGAIN TO CHECK YOUR WORK. |

||||||||